Hospitality | Residential |Healthcare | Education | Commercial

Both in personal cases solution and project construction, SILKROAD has professional guidance and experience.

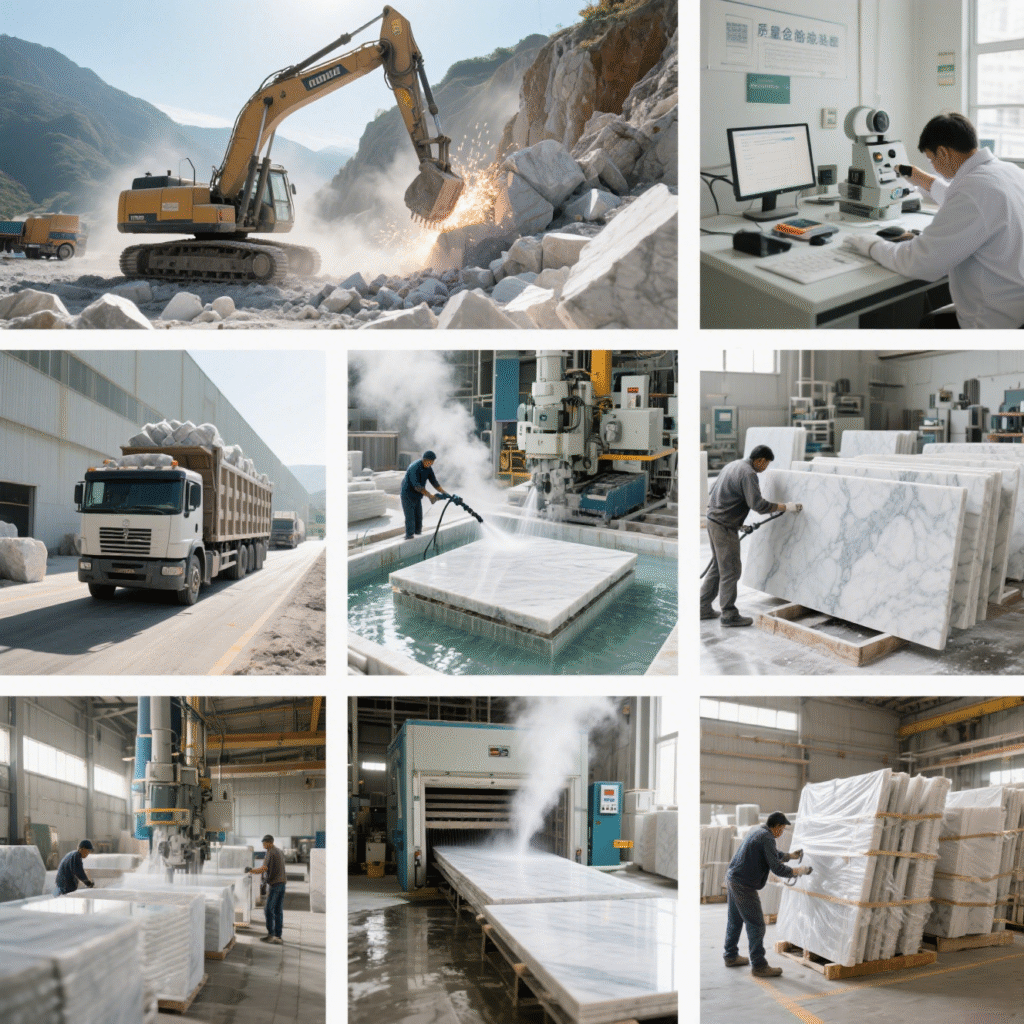

When it’s time to have your building materials shipped, Silkroad Buildings will provide packaging services to make sure your building materials arrive safely and securely in their destination. We use sturdy packing materials so you won’t have to worry about your materials being damaged while in transit.

20,000 m2 Showroom. One-Stop Solution. Easier To Solve Your Needs.

At Latest 30% Money Savings. Directly Buying From Factory.

Professional Sale Team,Door To Door Delivery,Installation Help

14 Years Cabinet Manufacturers Experience,Export To 120+ Countries

Global Sourcing , Partnering with World-class Brands to Offer the Product of Quality .2 to 5 Years Warranty for Products

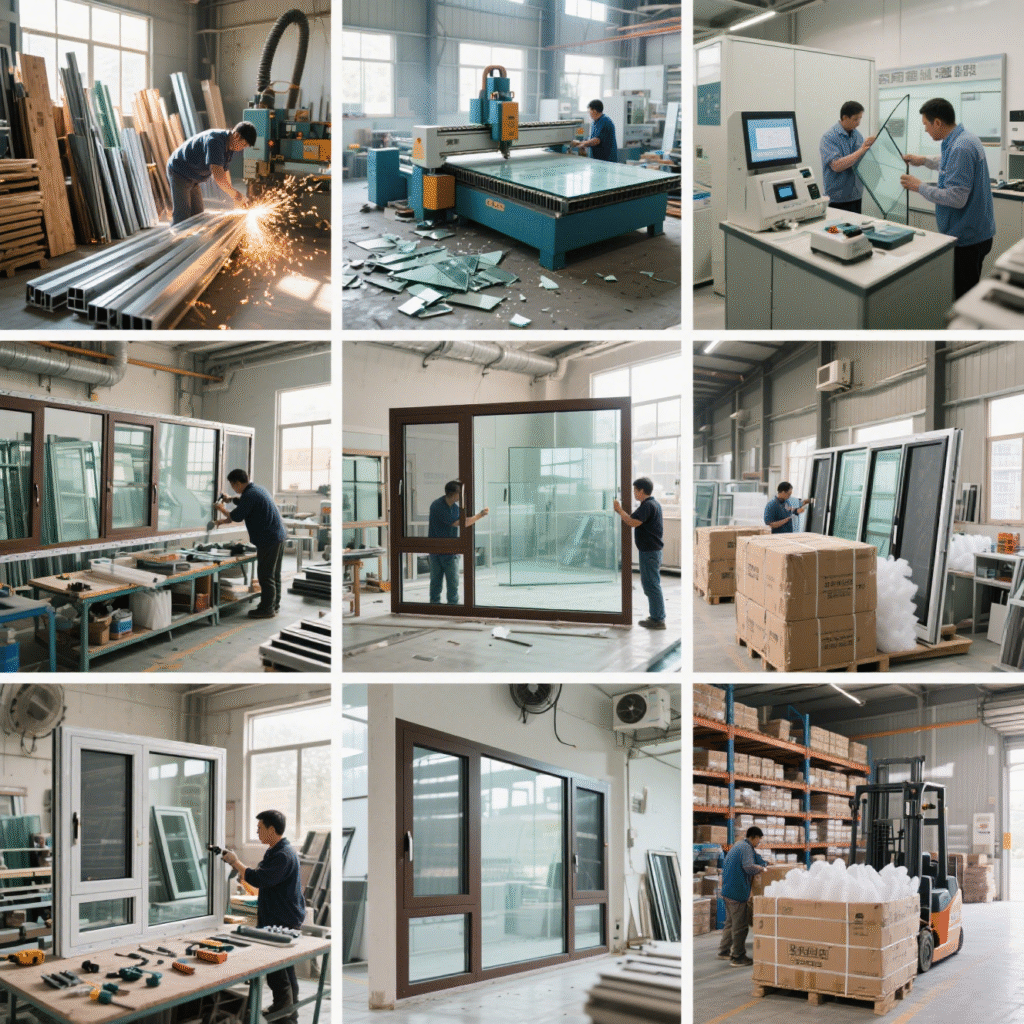

We Manage Every Step of Your Project. From Design, Producing, Delivery Containers to Your City.

Stay updated with the latest working process, product updates, and successful projects through various channels within our site.

Our case studies illustrate successful projects across diverse sectors, showcasing our ability to meet unique client needs while delivering quality and innovation.

We pride ourselves on positive feedback from clients worldwide, highlighting our commitment to excellence and customer satisfaction in every project.

Our streamlined process involves consultation, custom design, quality material sourcing, and expert project management, ensuring a seamless experience from start to finish.